Examples of automotive applications

Form your own impression of what we have to offer. Here you will find a selected overview of our application examples from the automotive sector.

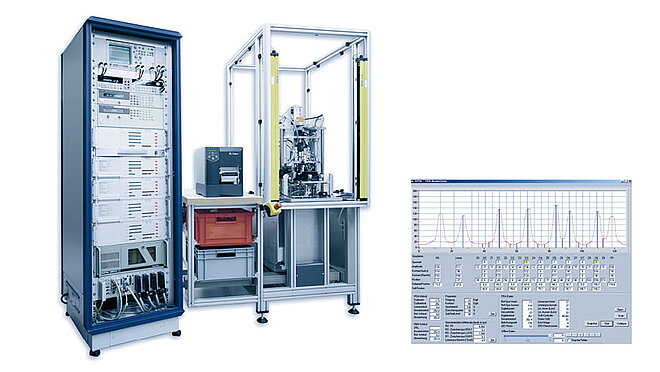

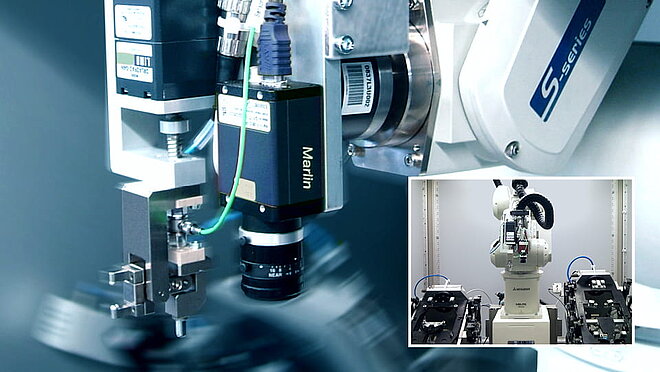

Functional testing system for a vehicle key ID sensor

Technology:

NI LabVIEW, NI TestStand, MS Visual Studio.net, Siemens S7

Tests:

FSK demodulation and data string analysis, ASK communication in the LF range, resonance frequency trimming of 3D transceivers, rest and operating current measurement of microswitches

Features:

Photo-realistic menu guidance, online visualisation of all test sequences at the stations, parts handling using SCARA robots, palletising and de-palletising, NOK handling, master part handling

Functional test system for optical steering angle sensors during product start-up

Technology:

TSA 4000 functional testing system with 256 test channels

Tests:

CAN communication, electrical parameters, data from a CMOS camera line, etc.

Features:

Measurement and evaluation of the rotor torque (in Ncm), test adapter based on flexTAC®-basis

Inline functional testing system for door control units in production

Tests:

CAN communication, electrical parameters, Hall sensor functionality, fault memory evaluation, etc.

Technology:

linear transfer system with coded workpiece carriers

Features:

Parallel functional testing on three test specimens, integrated leak test, control computer concept, automated identification, automated OK / NOK separation and palletising

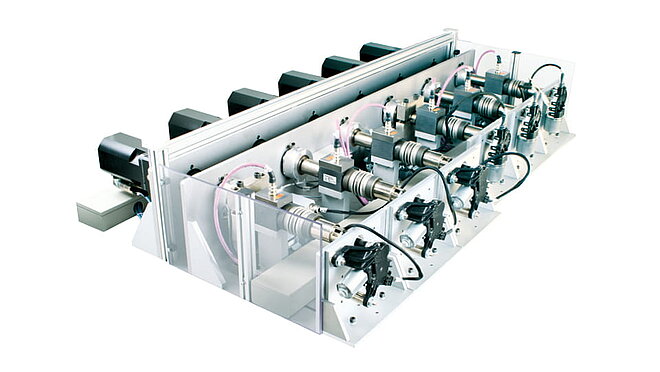

Endurance testing on windscreen wiper drives

Tests:

power consumption, motor voltage, maximum speed, angle of rotation, etc.

Technology:

load simulation with controlled AC servo/gear combinations

Features:

different load profiles for intermittent and rear wiper motors

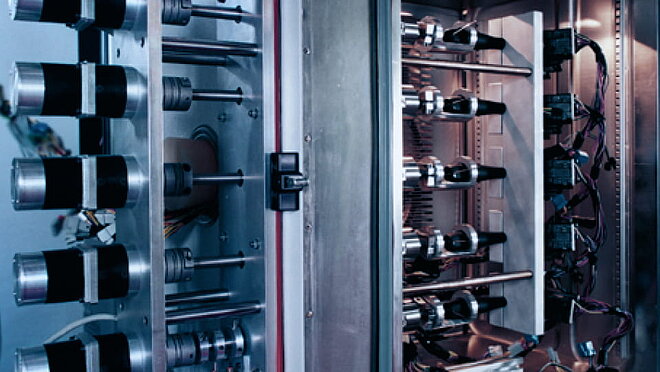

Functional testing on starter generator systems for hybrid vehicles

Tests:

converter tests, recuperation test, charging and holding currents plus internal resistance and terminal voltage of the ultra-CAP, LEM converters and insulation testing, etc.

Technology:

TSA 4000 test system in combination with current sources and electronic loads

Features:

Special requirements for low-loss power distribution and high-current contacting

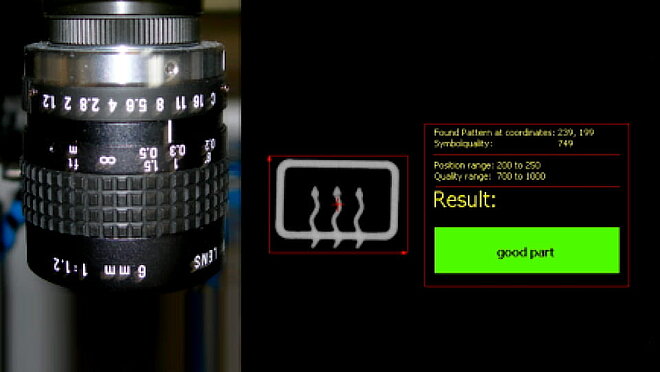

Automatic optical symbol monitoring and testing of the detection and functional illumination of vehicle control panels

Tests:

Optical inspection of version-specific symbols, lighting uniformity, testing for correct colour, etc.

Technology:

High resolution colour CCD cameras

Features:

Qualitative luminance evaluation

Test system for climate control devices

Tests:

Optical symbol and colour control (detection and functional illumination), haptic testing, functional testing

Technology:

6-axis robots, TSA test control, test head with colour camera and haptic test unit

Features:

Just-in-sequence production, high parts variance

Run-in test system for a steering column switch

Tests:

Switching function, voltage drop, etc.

Technology:

Translational and rotational actuation mechanism in the climatic chamber

Features:

Actuation mechanism outside the climatic chamber

Functional testing system for roll-over protection systems

Tests:

Extending velocity, retraction, triggering and locking force, etc.

Technology:

DMS force measuring technology, laser path measuring technology, measuring data recording via high-speed A/D conversion

Features:

Vibration decoupled test mechanics, sound muffled test environment