SOMA optical inspection

AOI – automatic optical inspection – originates from the production of electronic assemblies, where appropriate tests are conducted after assembly and soldering to assure subsequent functionality even before the functional test.

SOMA automatic optical inspection (AOI)

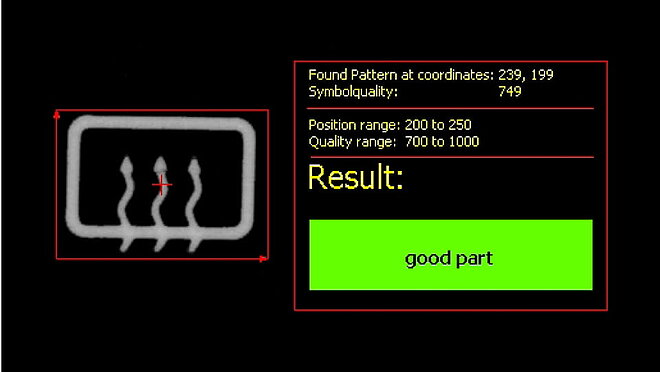

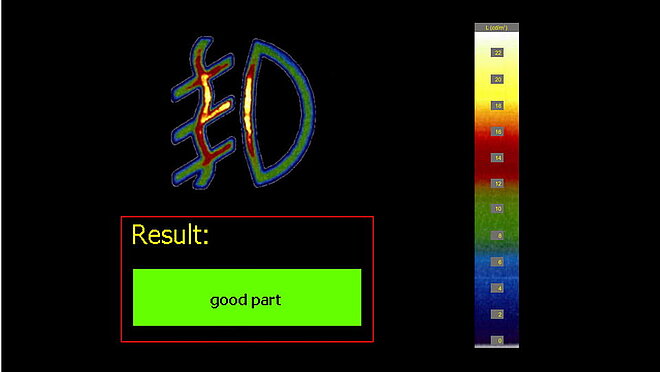

As an established test method, optical inspection detects product-specific features, such as the presence and dimensions of certain components, the quality of laser-applied symbols, the uniformity and colour correctness of LED lighting, etc. It is increasingly being used in the quality control of finished products and is thus becoming an integral component of 100% functional testing equipment for electronic and mechatronic products.

Industrial image processing from SOMA

For many years now we have used industrial image processing to realise complete application-specific system solutions and optical inspection systems for our customers, that have to prove themselves in industrial applications.

Even as part of preliminary investigations, we use our profound image processing know-how in the optical control field to select camera systems suitable for the respective tasks, determine the required illumination components and plan their integration into the test or automation systems.

Efficient tools and algorithms for optical inspection

We offer you test bench solutions from a single source by combining other testing technologies from SOMA Test Technology.

SOMA uses efficient image processing tools in the course of realisation. These enable both a targeted implementation of the task and the required performance in terms of evaluation speed and certainty.

Our customers are also provided with "on site" training to enable them to independently make the required parameter amendments to the image analysis algorithms in the event of minor product changes, thus ensuring a smooth production process.